Plastic Film manufacturers will be blown away by the AIR MIX KIT, the latest energy-saving device from process cooling specialists, IsoCool. Designed specifically for air blown film extrusion processes, the AIRMIX KIT is an intelligent energy saving device, which automatically mixes ambient air from inside and outside the factory, as well as via the air chiller, to achieve precise temperatures while minimising energy usage.

As with all free cooling devices, the AIRMIX KIT adjusts or disables the chiller compressor when the outside ambient is below a certain value linked to the set-point temperature, thus achieving up to 100% direct air cooling and significant energy savings. But the AIRMIX KIT takes this a stage further with its 3-way mixing by-pass shutter, a clever piece of technology which allows the unit to utilise an additional source –warmer ambient air from inside the factory. This enables the AIRMIK KIT to fine-tune the outlet temperature to within +/- 0.5oC of that required by the process.

The advantage of the 3-way valve is not only accurate temperatures, but also optimum energy-efficiency, as the AIRMIX KIT automatically adjusts the cooling feeds to maximise the free cooling function. For example, during winter months when the outside air temperature is at the required level below the set-point temperature, the chiller works only in free-cooling mode, with the 3-way shutter positioned to use the outside or inside ambient air, or both. If the temperature drops further, the unit’s microprocessor activates the 3-way shutter to mix the inside with the outside, in order to raise the temperature of the air to the required set point.

When the temperature is 5oC below the set-point temperature – such as would be the case during average seasons – the AIRMIX KIT combines the outside ambient with mechanical cooling to allow partial free-cooling. It is only during the summer period, when the outside temperature is higher than that of the air outlet, that the free cooling function switches to stand-by and the chiller system takes over entirely.

The result is that the load on the compressors will be significantly reduced over the course of a year, which not only saves on energy costs, but also increases the longevity of the chiller and reduces maintenance.

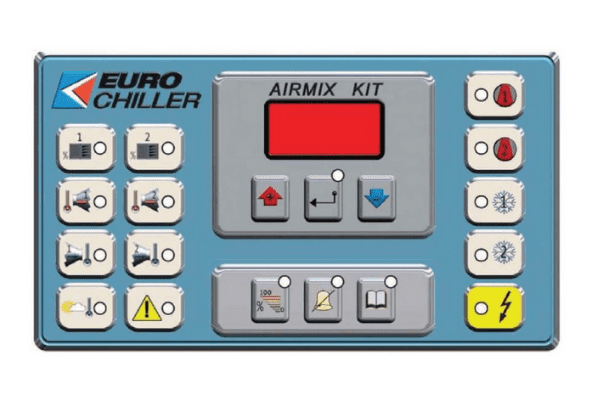

Designed for convenience, the AIRMIX KIT can be easily retro-fitted onto existing air chiller systems of any make, for immediate use. What’s more, it works automatically so is easy to use, and features a handy display panel which shows the current usage of the 3-way shutter and the process air temperature.