ABFevo INVERTER

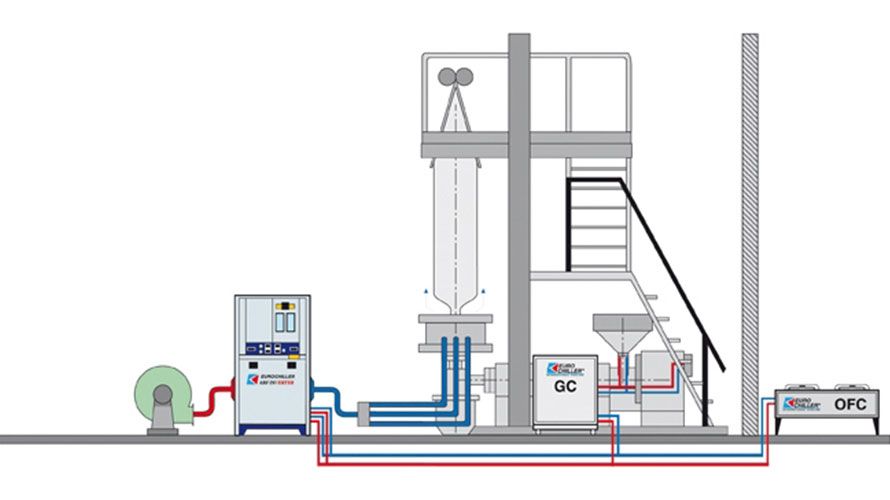

Inverter control for ABF linesThe ABFevo inverter is a blown film cooler that uses cutting edge cooling technology for air blown film lines and is indispensable for providing consistent film quality, reduced cycle times and optimum efficiency.

Blown Film Cooler

This ABFevo air cooling system, by direct expansion of the gas, can achieve savings of up to 50% compared to a standard chiller + air/water heat exchanger system and up to 35% if compared to the previous generation of ABF (air blown film) lines.

Main Features Of The ABFevo Inverter

- Constructed of steel panels painted with polyester powders

- Evaporator with hydrophilic fins

- Drops separator with built-in air filter

- Highly efficient Scroll compressors (refrigerant R407c)

- Modulating valve with hot gas by-pass system (HGBP)

- Available in 10 different models to suit all applications

- New inverter control allowing an intelligent control of the cooling capacity

- Easily inspectable shell & tube condensers

- Pressure switch valve adjusting the condensing water flow rate according to the working conditions

- Electric panel manufactured to IP54

- Multi-function microprocessor control panel with a 7“ touch screen display with simple and intuitive graphic symbols

The Energy-saving Benefits Of An Air Blown Film Cooler

In terms of energy savings, the ABFevo Inverter blown film cooler is up to 50% more efficient than a standard chiller and air/water heat exchanger set-up, thanks to air cooling through the direct expansion of gas, and up to 35% more efficient when compared with to previous designs of ABF Inverter. Most notable is the chiller’s inverter control, which not only keeps energy consumption and operating costs to a minimum, but also limits peaks in electrical usage, increases compressor longevity, and allows the process air to reach the set temperature value in a shorter time.

Find Out More About The ABFevo Inverter

For more information on the ABFevo Inverter and ABFevo Cooler, please get in touch and speak to one of our highly trained engineers. We can either use plant specifications to assist you over the telephone or arrange to visit your site if your blown film cooler requirements are more complex. Remember, we also offer a free energy saving survey, so if you feel your plant could benefit from a thorough analysis, please get in touch with Isocool today.