IsoFC Energy Saving Heat Exchanger

Dual circuits? Get dual benefits!Dual circuits? Get dual benefits with our isofc heat exchanger. You could be saving thousands of pounds per year on cooling costs and significantly improve process efficiency with this innovative equipment. The ISOFC is a high-efficiency packaged heat exchanger designed to significantly reduce energy consumption and improve process efficiency within dual-circuit systems.

How the IsoFC industrial heat exchanger works

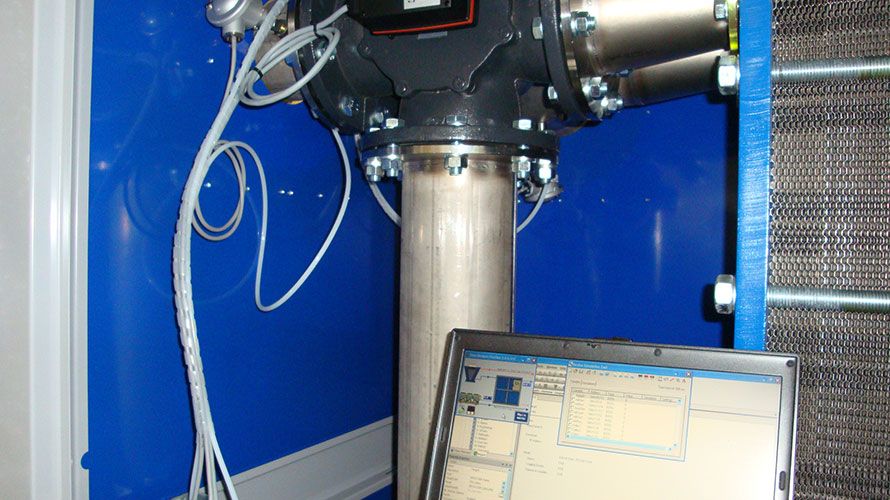

This device works by connecting mould and hydraulic cooling circuits through a high efficiency packaged heat exchanger unit with intelligent software, facilitating energy transfer between the systems without them mixing.

During low ambient conditions, the IsoFC uses the surplus capacity from an ambient cooling system to pre-cool water returning from the mould circuit before it reaches the refrigeration plant. The result is a fully optimised integrated energy-saving cooling system that significantly reduces the energy consumption of the chillers, while also extending their longevity.

Advantages of the IsoFC heat exchanger:

- Significantly reduces energy consumption

- Improves process efficiency

- Increases longevity of chiller plant components

- Reduces chiller maintenance frequency and costs

- ROI is usually 12-24 months and schedule is included in proposal

- User-friendly touch screen controls

- Enables SCADA interface

- Supply only or turnkey solution

- Can be retrofitted with minimal shutdown

- 20 standard models (duties of 50 kW to 1 MW) and bespoke systems available

- Manufactured by IsoCool in the UK

User-friendly and energy saving

A user-friendly touch screen controls the plant to optimise performance and to ensure close process temperature control on both circuits. In addition, the modular software design enables SCADA interface to computer and building management systems with power consumption monitoring.

Our flagship heat exchanger product, made in Britain!

IsoCool manufactures the IsoFC at our factory in Essex. We produce 20 standard models, complete with weatherproof enclosures, with duties of 50 kW to 1 MW. We also offer a bespoke design service to provide equipment that best suits your needs.

Offered as supply only or as a turnkey solution, the IsoFC unit can be retrofitted to any existing dual-circuit cooling system with minimal shutdown. Payback schedules for the IsoFC are usually between 12-24 months and we provide an ROI schedule as part of our proposal.

Comprehensive heat exchanger installation

Alongside our extensive range of process cooling products, our expert team can provide a seamless installation service, as well as supporting the continued operational efficiency of your business with regular maintenance. With a combination of market-leading, innovative products and extended services, we aim to protect the longevity of your equipment and ensure optimum performance for years to come.

Find out more about industrial heat exchangers and more from Isocool

In order to find the best solution for your application and budget, please get in touch and speak to one of our highly trained engineers. We can either use plant specifications to assist you over the telephone or arrange to visit your site if your requirement is more complex.

Remember, we also offer a free energy saving survey, so if you feel your plant could benefit from a thorough analysis, please don’t hesitate to contact us.